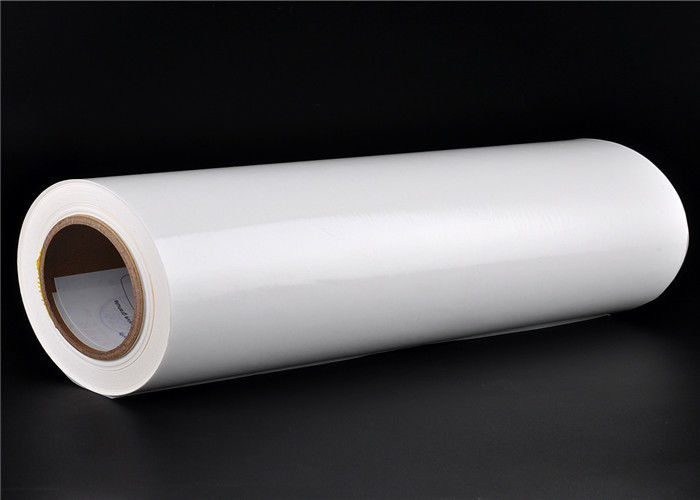

One variety of adhesive made of plastic is called hot melt, and its common name is "hot melt. "Although there is a change in its physical state in response to the temperature within a certain temperature range, the chemical properties of the substance do not change as a result of the temperature change. It is a chemical product that is beneficial to the environment, eva web adhesive does not have any flavor, and can be consumed without any concerns.

People almost universally have the misconception that thicker glue is better than thinner glue, but this is not the case with hot melt glue. To what extent does the viscosity of the hot melt adhesive play a role in determining the adhesive's consistency?.

For the purpose of conducting tests, we went out and purchased a wide variety of hot melt adhesives from a variety of different manufacturers from the market. We will apply each type of glue that we will be comparing to the same material so that we can evaluate how well each type of glue adheres. In order to ensure that the results of the tests can be referenced accurately, eva web adhesive the application environment of each glue as well as the bonding materials have been standardized.

The following conclusion was reached after a number of experiments were carried out and the accuracy of various instruments was evaluated: when taking eva web adhesive into account hot melt adhesive as a single entity, the thickness of the adhesive does not have a direct relationship with its viscosity. However, the adhesive effect that is displayed in the actual application does not fully represent the true viscosity performance of the adhesive. This is because the viscosity of the hot melt adhesive can remain the same regardless of how thin the adhesive is. There is a reference value that can be used to determine whether or not the various adhesive applications being considered are applicable. It is possible that a change in the proportion of one particular ingredient will result in a change in the physical value of viscosity and thinness; however, this factor cannot explain the problem on its own by itself.

They are simply individuals that are contained within the parameters of hot melt adhesives, and the comparison of parameters is the only way to determine the accurate value of each individual parameter. It is completely unimportant for you to worry about the relationship between the viscosity of hot melt adhesive and the consistency of the adhesive itself. If you are having trouble bonding, the most important thing for you to do is to pinpoint the problem as soon as you possibly can. This is the most important eva web adhesive thing for you to do.

When working with hot melt adhesives, it is almost certain that misunderstandings will arise at some point. This is because of the nature of the adhesives themselves. What are some possible solutions to this issue?The vast majority of people will have some level of familiarity with this hot melt stick. This is due to the fact that it is typically utilized when we are bonding objects, as well as the fact that the process of using it is relatively easy and uncomplicated. In the course of carrying out the procedure, there will invariably be a few instances where the meaning is misunderstood.

A common misunderstanding is that hot melt adhesives can produce some odors that are disagreeable and acidic while they are being used or while they are being constructed. Due to the fact that these odors are poisonous and hazardous to human health, it is impossible to use them in any capacity that requires prolonged contact or work involving construction. The correct explanation is as follows:It is possible that certain acidic odors will be emitted from hot melt adhesives during the construction process; however, these odors are not harmful because the primary components of hot melt adhesives are EVA resin, thickeners, and antioxidants. This is an exceptionally risk-free and safe adhesive to use.

Misconception number two: hot melt adhesives cannot be used to bond metals, ceramic tiles, electrical appliances, or electronic devices; they are only suitable for use in bonding fibers, paper, plastics, and wood. Because it can still maintain good bonding performance while at the same time simplifying the construction process, it is particularly useful in industrial manufacturing. This is because of its versatility. This product is perfect for the routine maintenance and repair of electrical appliances and electronic devices due to its small size, resistance to falling off, and transparent color. These characteristics make it ideal for these tasks. If this step is skipped, the temperature of the area will rise to an unsafe level, and the adhesive will be more likely to melt. Explanation that is accurate: Whenever hot melt glue is used, it is necessary to apply it using a glue gun. It is not necessary to remove the adhesive strips that were used in the operation and construction; rather, they can be used directly for the next time. This is because the melting point of hot melt adhesive is 85 degrees, so there is no need to worry about it melting, and it is also not necessary to remove the adhesive strips that were used. The range of applications that are utilized further downstream is continuously expanding. This market represents the largest proportion of the total. Residents of China are paying an increasing amount of attention to the quality of the packaging of various goods, including food, beverages, and other products, as a result of an increase in the level of consumption as well as a shift in the concept of consumption. This is because both factors have led to an increase in the consumption level.

Within the context of the packaging industry, what kinds of specific applications are there for hot-melt adhesives?Sticking of straws: products such as milk, tea beverages, and other paper packages are attached to the straws, the curing time of the hot melt adhesive is required to match the speed of sticking the tubes, and the high and low temperature resistance of the hot melt adhesives is matched with the existing environment of the product;ice cream cartons, snack food, etc. , automatic packaging production; PET transparent box sealing: such as Packaging candy, biscuits, frozen food, and ice cream cartons; carton sealing: such as Packaging candy, biscuits, frozen food, and ice cream cartons;.