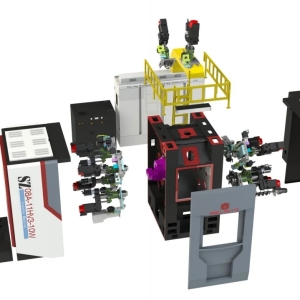

servo control wire cutting machine is mainly composed of three parts, which are: Machine tools, CNC systems and high-frequency power supplies, can cut materials, such as high strength, high toughness, high hardness, high brittleness, magnetic materials, as well as precision small and complex shape parts, are widely used in all walks of life, and other machine tools are different. servo control wire cutting machines offer advantages in the following areas:

1, environmental protection: fully enclosed cover, the wire path are waterproof plate and wire anti-splash protection device, can effectively reduce the cutting liquid splash during processing, protect the environment.

2, convenient: the host control is equipped with a manual box, the operation is more convenient. Intuitive, clear and practical all Chinese interface, to achieve human-machine dialogue. The industrial computer is equipped with RS232 communication interface and USB interface and has LAN interconnection function.

3, accuracy: X, Y axis using Japan THK or China Taiwan high-precision linear guide, double nut ball screw, with pitch reverse gap compensation function, greatly improve the positioning accuracy.

4, strength: column type low center of gravity T-bed structure, high strength resin sand casting. The main machine has sufficient rigidity and strength, which can ensure the accuracy of the machine tool for 5-10 years.

5. Power supply: servo control wire cutting machine adopts the most advanced pulse power supply, which can output large current, achieve high speed, output ultra-small pulse width, achieve high precision and high finish.

In the use of servo control wire cutting machine, if the equipment fails, the user can make the right medicine according to the specific fault form, among which:

1, boot processing, electrode wire does not go, Other functions are normal: Pay attention to the part of the wire driving mechanism, and find that the rubber pressure wheel has been pulled out of a deep groove by the electrode wire. The electrode wire is deeply stuck in it, lift the roller Rx2, correct the traction motor rotation, but can not drive the electrode wire, replace the rubber pressure wheel or transform the rubber pressure wheel, because the outside of the wheel is blocked by several washers and fastened with nuts, remove the wheel, and make a thickness of about 1.5mm gasket with the shaft on the side of the wheel * bed; Install the washer first, and then install the rubber pressure wheel, the outside of only one washer, and at last tighten with the nut, after the above treatment, the electrode wire is allowed to open the groove of about 2.0mm, the pressure wheel can continue to use.

2, the machine has no automatic threading action, manual threading processing: according to the circuit principle block diagram, the automatic threading motor is measured with + 15V voltage, no threading action, indicating that the circuit works normally, the threading motor has a problem, the load is removed, the motor can rotate, but the noise is large, after replacing the same type of threading motor, the machine works normally.

servo control wire cutting machine https://www.talentcnc.com/Medium-speed-SERVO-wire-cutting-machine